Sea Water Intake System Design Proves Problematic

- Chris Leigh-Jones

- Apr 1, 2023

- 4 min read

Updated: Apr 20, 2023

Installation of John Deere 4045 diesel engines is now underway on our expedition yacht, allowing us to examine the seawater intake system design in detail and finalize the various components. To our slight concern, we noticed that the existing sea water intakes looked very useable from within the engine room, but the outlet fell some 8" below the lightship waterline. Any rolling or seaway would likely result in unwanted air entrainment.

In the drawing the purple pipe is the initial position at 8" immersion, red pipe approximate final position at 39" immersion.

These things happen occasionally and we had time to make modifications. We repurposed the existing inlets as overboard discharge points for the various ship systems. So nothing is lost in cost or time.

Turning firstly to the consumers, we have two John Deere engines, a Dolphin watermaker, Webasto HVAC condensers, and an SW washdown. The engines are the largest consumer with a 2" or 50mm cooling water line.

Seawater intake Filter

We also consolidated all seawater inlets in a single location and to have a duplex sea suction filter arrangement capable of complete flow demand through either filter. Every hull penetration is a potential point of failure, so it is best to minimize those we have.

Seawater Intake System Requirements

A second requirement was to meet the conditions stipulated by UK MCA Category (0) Classification. They are prescriptive. Variations are allowed and subjected to a time-consuming approval process, and as we do not have the luxury of time or surety of success, it was prudent to comply. Comply with what, though? We looked at quite a few examples covering FPB 70, Bering 70, Fleming 65 built to ABYC or EU standards but none gave guidance for MCA (I believe one FPB was built to Category (0) though information is hard to track down). All ship side valves must be fire rated, a.k.a; remain in serviceable condition under a 30-minute exposure to extreme heat. That means the only option for us was metal valves. Our preference for fiber-reinforced composite valves such as TrueDesign or Forespar would not be allowed due to missing certification.

Seawater Intake Pipeline Design

The same stipulation applied to all piping and the sea suction filters (outer container only).

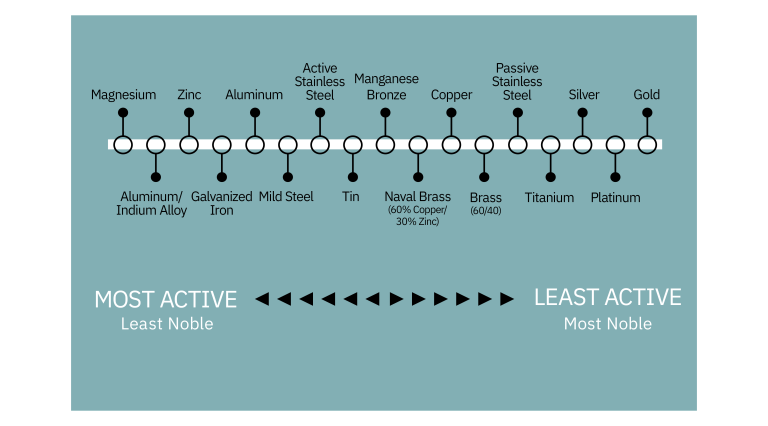

We have an aluminum hull. Electrolytically compatible aluminum valves are unavailable, so bronze or stainless steel was the next choice. Read the literature, and you will find both being used successfully and less successfully, plus all points between dependant on anodes, passivation, isolation, or other random reasons. Our pipework was also limited to metal or fire-rated exhaust hoses (typically those blue silicone ones). This also thankfully removed the need to consider bronze and mixing metals within a system.

"From MGN 280 - UK MCA Category (0);

5.8 Materials for Valves and Associated Piping

5.8.1 A valve or similar fitting attached to the side of the vessel below the waterline, within an engine space or other high fire risk area, should be normally of steel, bronze, copper, or other non-brittle fire resistant material or equivalent."

S/S 316L can be subject to crevice corrosion, especially under anoxic conditions. Welded construction also has a weakness in the Heat Affected Zone (HAZ) that are less resistant to corrosion; overall, this made us nervous, given the location below the waterline. We eventually found a seawater strainer using cast instead of fabricated construction, free of HAZ zones and made from AISI 2205 duplex stainless steel specifically for this application and superior to 316L in all ways. We can further isolate with the butterfly valve liners being a rubberized material and fitting insulating washers under clamping nuts. Sometimes fortune smiles on us!

Cast stainless steel 3" sea suction strainer with a composite basket (middle example, bottom inlet).

Seawater Intake System Design - Our Final Vanguard Yacht Design

Our final design allows for operation under a single or duplex sea suction filter, either one feeding both systems or isolation of a single system with the other remaining in operation. All valves directly connected to the sea will be stainless steel body & composite coated butterfly types.. These are open/shut with no flow control requirements and low maintenance. A flexible seawater inlet that reflects standard commercial practices from much larger vessels.

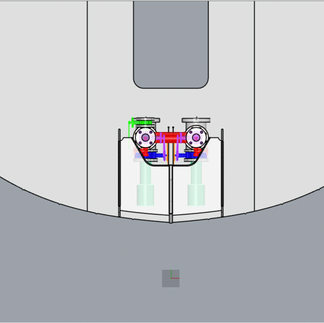

This is the final arrangement utilizing an empty and accessible space under the floor plates.

The sea suction was repositioned lower in the hull, providing for around 1M (39") of immersion, a distinct improvement on 8". If we sit the hull on the bottom under any circumstances, they best be shut. Apart from that, we should be good to go. We located two 3" seawater suction strainers at Fisheries Supply. Each can handle 2.5 times the maximum flow needed, so we should be protected from weeds, plastic bags, or slush ice blockage by their volume and slow flow rate. An air supply point is available for clearing the worst of it, and they can be isolated at sea for servicing. We did consider placing them such that the open end was above sea level, though for the location, that would result in the clutter in the engine room, so we opted for valve isolation instead.

So there you have it. Our seawater inlet and filtration are flexible and tucked into an unused part of the engine room floors. It is fully stainless steel and fire rated in compliance with UK MCA commercial requirements. Finally, some thoughtfully placed additional anodes will protect it from galvanic corrosion.

Chris Leigh-Jones

Years ago, I worked voyages down the coast of West Africa. A frequent stop was Apapa, the port for Lagos, Nigeria. Modern ships by the day's standard, with engine rooms unattended at night. Woe bedites the duty officer who did not prepare that machinery space for bed of an evening. Sea suction filters and bilges were the prime suspects; plastic bags would ruin a good night's sleep for the former. I doubt that situation has improved over the intervening years.

Polish built MV Sherbro, sister ship MV Shonga of Elder Dempster Lines, Liverpool. 9340 GRT, on the EU/West Africa trade. Acknowledgement "The Allen Collection".

Read also: Wet Exhaust - Developing Basic Design Rules

Read also: Yacht Fuel and Water Tank Capacities