How to Launch Our Explorer Yacht Tender?

- Chris Leigh-Jones

- Dec 14, 2022

- 3 min read

Updated: Mar 23, 2023

Designing a yacht is a perennial process of compromise across multiple competing parameters.

Size vs. weight

Functionality vs. complexity

Location vs. trim

on and on.

Such was the case in understanding how to quickly and safely launch a tender from the aft deck of Vanguard.

Lifting the Yacht Tender

Lifting the yacht tender is a problem that we believe was already solved. "Fit a small knuckle crane near the rear engine room access; finished." The weight of the tender had crept during the design from 1000 to 1250kg, so the crane size had to increase, resulting in a 1000kg dead weight in one of the worst places possible.

It disturbed the trim. Additionally, the idea of a willing 14-year-old lifting a 1250kg tender with a 1000kg hydraulic crane and accidentally hitting something or someone along the way was a risk too far. So we went back to the drawing board. We considered two options. Scrap the crane, fit a boom or a derrick(s). The first is an easy choice, often used in pairs with the dual use of deploying a flopper-stopper type stabilizer.

We did not have such a device, so it required only a single boom. The superstructure also needed to resist the considerable horizontal force resulting from the topping lift ropes.

The yard kept saying, "it's ugly," and generally refused to play with the idea. In hindsight, they were probably correct.

Image shows derrick and flopper stopper arrangement on an FPB64 seen motoring at 8kN on the US East Coast intercostal waterway.

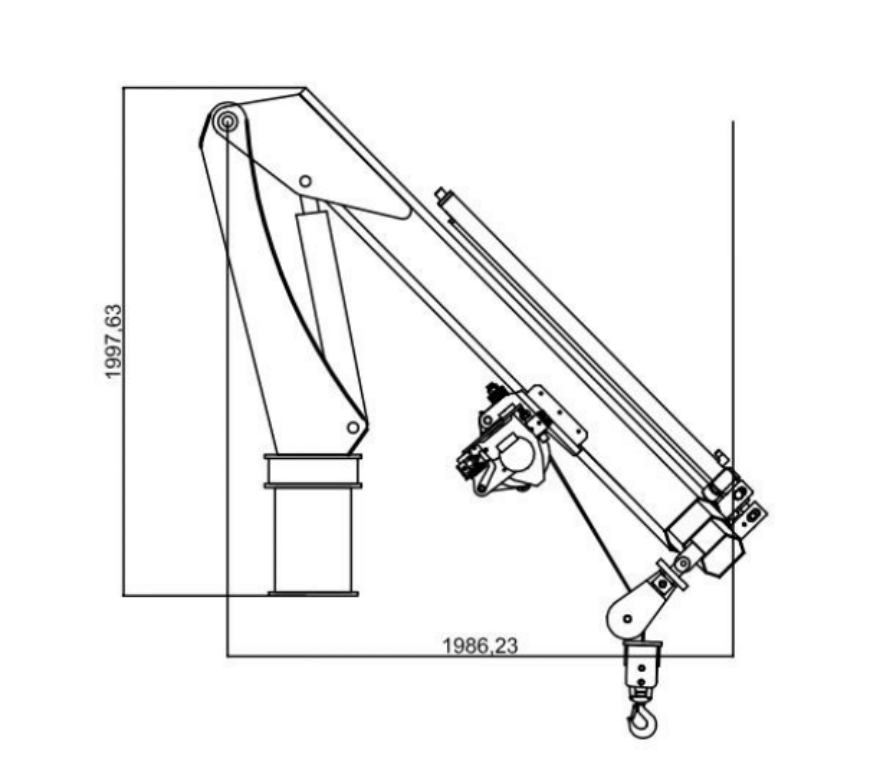

The next idea was to research a derrick or twin derricks. We needed something that could safely lift 1250kg plus a bit. It needed a lift height greater than 2.5m toiler 1.0m railings and reach (2<>2.5M). The usual suspects of hydraulic cranes that we find on yachts do not fit in size as they tend to be constructed for smaller RIBs and jet skis or are large and relatively expensive. I also wanted to avoid the ongoing complication of different hydraulic systems that are notoriously unreliable. If this breaks down, we are without a tender; this is not great.

So we then started researching who makes suitable derricks out of metal or composite. There are surprisingly few firms, but we located two, Atlas in the UK and FEM in Italy (details below). As time was tight, we ran with FEM inside the EU with more accessible transportation to Turkey. As per the table below, our initial contact started configuring just what we required.

Lift | 1500kg SWL 3x Safety Factor |

Reach | 2 - 2.5m |

Clearance | 2.5m clear to the railings |

Winch | 24 VDC Duel Direction |

Slew | Hand push or manual crank |

Weight | 80kg, including location sleeve and winch |

Orientation | Foldable to minimize footprint |

Material | Carbon Fiber for min weight, painted for UV protection |

The last criterion was not strictly necessary but did limit maintenance. A 24VDC Harken winch also has a manual operation, so we lose the additional hydraulics. Working force on the manual winch options 9kg, enough for a work out but not excessive..

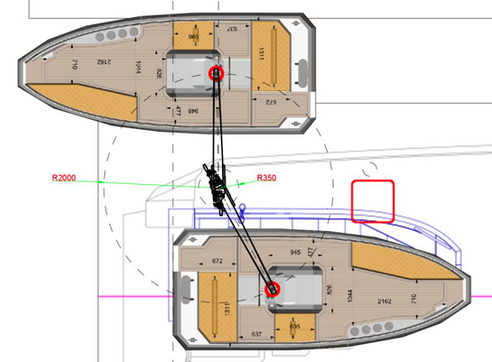

Lifting the Yacht Tender - Geometry

We had a few rounds of discussion to confirm the geometry for the lift. The Derick block needs to be vertically above the horizontal Centre of Gravity of the tender, so it lifts cleanly, and when dropping into the water, we need to clear the yacht side. We needed to lift high enough to clear the railings and not impact the aft deck roof. We also needed to drop on the port side and preferably astern.

These carbon fiber derricks are remarkably light, removing some 900kg from the stern of Vanguard. We may need to adjust any list with additional ballast, but weight is far easier to add than to remove. We examined a 2.0 and 2.5m reach plus various location options. Another feature is the ability to fold the derrick and move it to other locations when not in use.

We have picked 3 locations:

Port aft

Starboard aft

Foredeck.

The derrick comes with a fixing plate so it can be detached from its location and moved to another convenient spot. these plates are welded in to the aluminium deck structure.

So we now have a facility for stores / maintenance, launching the tender, and satisfying the requirement of a personnel hoist for Man Overboard situations. And all within 80kg.

Sometimes we have a good day!

Chris Leigh-Jones

I remember sailing down West Africa's coast years back on an Elder Dempster Line ship. We dropped the lifeboat at the wharf in Appapa (Lagos, Nigeria) for a jolly round the harbor. When we returned, the tide has brought a 3-foot swell; it was a divine intervention that no one lost any fingers getting her back on the lifting eyes. Stowing a tender is not without its risks.

Getting a dinghy off the boat quickly is a serious safety concern. Hope you add a 10' inflatable with 12v inflator and a small outboard. I expect it won't be long before you'll use it more than the big one. And, it can be carried far enough up a beach so you can enjoy dinner in the Bahamas without worrying about the tide.

How about having two of these derricks for "tandem" lifting?

Lifting a heavy tender in any swell is rather "sporty". Tandem lifting is much much more safe, and you get to keep all your fingers as a bonus :)

Andy