Damaged Water Pump Nearly Destroyed our John Deere Engine!

- Chris Leigh-Jones

- May 31, 2025

- 3 min read

A simple check that could save your engine. Vanguard is fitted with two John Deere tractor engines. Specifically, 4045 AFM 85 M1-rated for continuous operation. The same power plant as the FPB 70 and many local, smaller fishing boats. Each engine has logged <500 hours, and when operating, we are quite careful to inspect them carefully after starting. The story follows how one of them nearly self-destructed.

What nearly wrecked our engines?

As we prepared to depart from Charleston, SC, for Georgetown, a routine inspection revealed an alarm on the Port engine's wet exhaust. We could find nothing wrong with the engine or the transducer. This incident underscores the importance of our habitual inspections when the machinery first starts. A quick trip to the engine room and a strange, hot plastic smell? The Port engine was good. A hand laid on the Starboard engine Halyard wet exhaust muffler prompted an immediate engine shutdown - no seawater cooling!

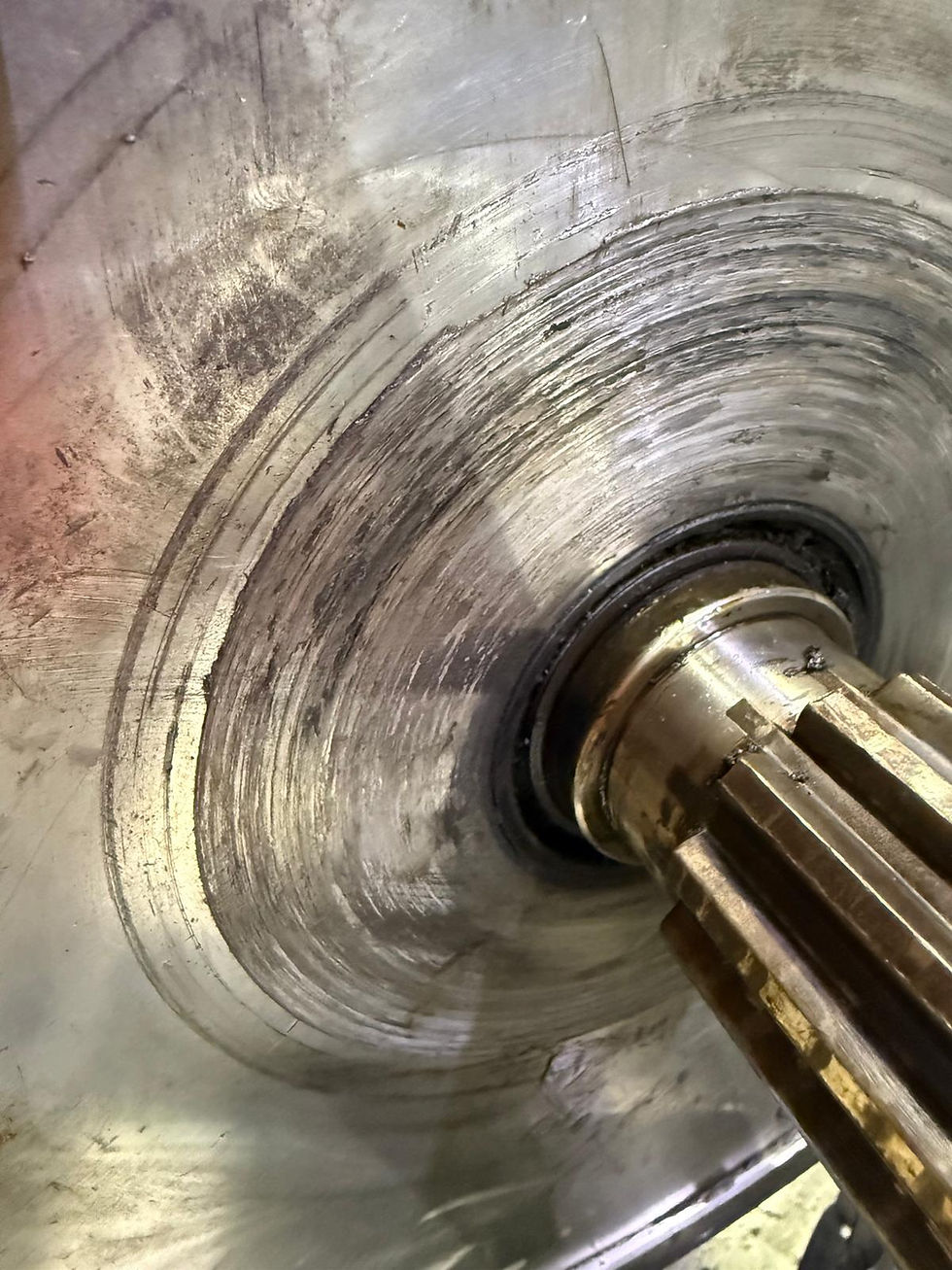

Upon discovering the issue, a first check was the sea suction filter (clean). We then checked the raw water piping as it ran over the engine; it should have been cool, but was rather hot; it should not be so! We then did a tertiary check of the engine for overheating damage (basically knuckle-dragging over components). The raw water pump was removed with some effort as it was difficult to access. Opening the end plate showed that the rubber impeller (Item 12) was in good condition, BUT as it turned, it took with it the CAM (Item 9 in the drawing). The pump would not, could not, work in this condition.

They say, "God loves a sinner." It's true; it was a timely intervention, and we were able to prevent disaster. We carry sufficient (expensive!) spares, so our replacement pump was fitted. The system restarted before checking that all was well, with seawater circulating as expected. Now for the investigation.

So What went wrong with the water pump?

The earlier exhaust alarm was real, but the engine alarms were wrongly wired. The Port was connected to Starboard and vice versa. We were looking at the wrong engine; perhaps we should have known better, but that's hindsight. Next, a small stainless steel stub bolt (Item 6) secured the CAM (Item 9) within the pump body (Item 18), which had broken at the thread, allowing the CAM to spin with the impeller. No signs of shear; it was a fatigue crack across the bolt. Looking at the CAM, it was poorly fitted in Turkey, with a slightly smaller radius than the pump body. As the impeller rolled over, it would cause this component to rock slightly, stressing the bolt and ultimately leading to fatigue failure.

The CAM was expanded slightly to suit the pump body radius. Then the fit was checked with a feeler gauge, and finally the impeller was reassembled.

After identifying the issues, we proceeded with the necessary repairs. The old, damaged thread was carefully tapped out with a punch, and a new stainless steel stub bolt was fabricated from our spare parts. We then used a vice to adjust the CAM, increasing its outer radius until it matched the pump body's, preventing further rocking. The assembly was refitted with semi-permanent Loctite for peace of mind. We also replaced the impeller before returning the assembly to our spare parts. Finally, we verified that the temperature probes were now correctly indicating the exhaust temperature of the repaired engine.

Left unnoticed, it was only a short while before this engine risked serious damage or destroyed itself, and the wet exhaust. Anyone running a John Deere Marine 4045 can easily remove the cover plate (Item 10) and use a feeler gauge to see if the CAM fits properly around the circumference. I encourage you to check your own engine. An overheated engine? It's best avoided.

As we work our way from Turkey across the Mediterranean and then up the US East Coast, what was mechanical disasters, frank ineptitude, an a leap in to unknown has been replaced with smaller problems, and these in turn are replaced by mainly niggles. This is a process to rebuild, fix, rectify, document, and move on. One day soon, it will just be a big adventure that represents the journey.

Chris Leigh-Jones

We greatly thank Brian, Sergii, Chris, and Keri of W.W. Williams for their sterling support late Friday night! They are the local Charleston JD Marine specialist. Despite it being late on a Friday holiday weekend and our low expectations, they sent a technician immediately to assist in determining what was happening and what support was needed.

Tel +1 843 225 7121

I have preached the value of wet exhaust temperature alarms for decades, they have saved many a cruiser's engine from major damage. https://stevedmarineconsulting.com/onboard-alarms-part-i/ I'm glad you had this feature, even if it was cross wired. As it did not fit properly, it sounds as if the cam is the incorrect part for this pump, rather than being "poorly fitted"? There really is no way to fit a can incorrectly other than not tightening the securing fastener. I have encountered this failure on several JD engines in the past few years, as recently as a week ago, all 4 cylinders. This appears to be an inherent problem. More on raw water pump service, cams and retaining fasteners here https://stevedmarineconsulting.com/raw-water-pump-service/

I like to check for good water exiting the side of the boat for both mains and gensets. How does it work with your glycol cooling ? Or is that just for the electric motors ?

That is a shocker, Chris. Was that water pump an aftermarket item – I cannot believe that it was a John Deere item. Or was the marinising of those tractor engines done in Turkey? In any case, well spotted. Our new boat has keel cooling and a dry stack – as many commercial vessels do. I'm so pleased that you were able to find this problem in time.