Communication is Key: Building a Working Relationship between Shipyard and Owner

- Chris Leigh-Jones

- Dec 2, 2023

- 6 min read

The relationship between an Owner who commissions a project and a Yard who builds it will span several years. The best projects start and end with a basic understanding between the parties of how responsibilities fall and how each contributes to its success. Treated sensitively, this can be a fun experience, ignored, and contention will arise early on, always to remain.

These notes are written from personal experience building our Explorer Yacht Vanguard, plus input from others in the business. There was room for improvement and we hope they are useful. Remember, if you have questions or wish to explore any aspect of your plans, we and the team at Artnautica remain an "email" or "WhatsApp" away.

Best regards, Chris & Sebrina Leigh-Jones

How the Process Unfolds

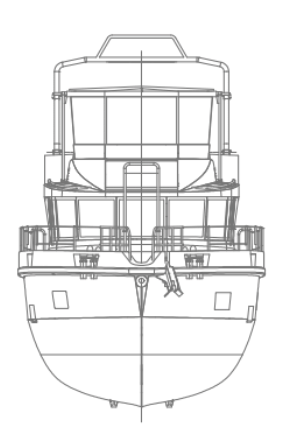

XPM-78 is a semi-custom, proven explorer yacht concept. The form and layout design is produced by Artnautica, and the engineering and implementation are the responsibility of Naval Yachts. XPM designs have evolved considerably during the construction of the first two hulls.

Within the confines of form and layout, the Yard will customize the Owner's specific requirements in each boat's technical specifications. This is the basis of your build. Each contract has 3 main annexes: Technical Specification, Preliminary Build Schedule, Payment Schedule (the Yard's cash flow)

An Owner may tend to treat the design as their personal plaything and this will cause issues. We encourage including a significant amount of equipment or layout used on previous builds. Known quantities will reduce the uncertainty. The first hulls were built by sailors with marine experience in their respective fields, lean on it for less delay and a faster build.

100% detailing each document is challenging; it should be developed enough to provide information so the Yard and the Owner are clear on intent but remain willing to review.

Under the guidance of the technical specifications, the engineering task can commence. Some engineering findings will affect one or all of these documents. Open and comprehensible communication on these occasions is paramount.

It is tempting to design as you go along, in the field, on the spot. Avoid that temptation and confirm all you can reasonably achieve at an early stage. Going the "semi-custom" route will help considerably. We also strongly suggest that all "Engineering and Design" functions are completed BEFORE the build starts. It's the cheapest place to make changes; you will be thankful for this later.

Naval Yachts are ISO 9001-certified; "If you can't measure it, you can't control it." Ensure that this process is adhered to and not used as window dressing. ISO9001 does not ensure quality; it should ensure consistency and traceability.

The Yard will build the vessel using its staff and subcontractors. Problems will always occur during the build and will be addressed as they arise rather than holistically. Be ready to have those conversations in real time.

Yacht building is an intricate business. It often needs to be more appreciated by Owners viewing a project remotely. Affirming new ideas is a common mistake in a Yard/Owner relationship, even when they may not be beneficial in the long run. So, be accepting of pushback when decisions are questioned. Remember also that Yard's are not sailors, they think "build ability" an owner should think "practicality".

Changes in the layout or specifications after the initial stages can disturb workflows and increase costs significantly; direct labor is usually a minor part of the total impact. Yacht building is costly due to complexity and construction's one-off nature. Furnishings that would be affordable in a regular retail setting become exorbitant in a boatyard. Expect some interesting Change Orders if you go down that route.

The build process must secure a reliable cash flow, if an owner defaults (it happens), finding a new project may take a year or more, leading to substantial losses, so a Yard must plan payments for work and profit to date.

Yachts should only be moved to the water after completion or risk a considerable increase in labor hours and costs to complete. Premature launch also results in a knock-on effect on subsequent projects. Despite any delay, the monthly fixed expenses for the Yard continue.

Express opinions but be careful not to take authority over what you cannot control, you take it, you own it.

The Design Phase for your Yacht Project

Maintain realistic expectations during the design phase. Define goals based on known, achievable parameters agreed with the Yard. Regularly review those goals.

Limit exploring novel concepts to minimize the impact of unforeseen challenges. When new ideas are introduced by Owners, owners will need to retain responsibility for the learning curve of new equipment.

Any and all changes will likely affect performance in some way, however subtle. Allocate safety factors to mass, budget, or center of gravity. Make sure they are tracked throughout the build.

Yacht building is an imprecise science. Underestimate performance indicators, such as range or tank volumes, as adjustments will likely be necessary later on.

Stay vigilant about potential side effects or issues that could arise during the design process. Consider alternative solutions in case of significant problems, and be prepared to adjust your course early on.

Regularly revisit initial decisions and goals as the design evolves, avoid conforming to the status quo out of habit, and prioritize simplicity, sea comfort, and speed. An owner's idea of "acceptable" may differ greatly from the Yard's; regular and clear communication is important.

The Build Phase

Monitoring project progress can be challenging, but breaking the project into manageable parts with assigned labor hours and timelines can help track trends. If delays occur, ensure EARLY discussion of how to get the project back on track; do not just accept platitudes.

Assumptions in the early design and cost projection stages should be revised as data changes. For instance, any enhancements that influence internal structure or weight should be monitored, and their influence accounted for.

Change orders should be minimized to prevent schedule disruptions and maintain the owner's funds. They often result in domino effects on the production line. Above a de minimus figure, change orders will be implemented once the agreed payment is made. All changes requested should be documented with Change Orders, including the effect on delivery dates.

Judging the quality of the build is tricky during construction, as protective covers conceal the finished work. Ultimately, you'll rely on the reputation of the team you're working with and feedback from previous clients.

The desired level of fit and finish significantly influences cost and construction time. As perfection is approached, costs and time can escalate exponentially.

Early system testing is essential to detect and rectify errors or malfunctions before leaving the Yard. It's also necessary to constantly update as-built data as the project evolves from the original design.

Schedules are inevitably going to shift. Yards should resist the pressure to prematurely move the yacht for launching, as this only escalates costs and delays the project.

If problems occur with the Yard, resist the temptation to order "STOP," pay what is due, and discuss the disagreement. The financial leverage tool should be used sparingly, or relationships will be permanently damaged. This is no place for a bully.

The owner should only move aboard or bring personal items after completing sea trials. This can significantly hinder sea trial progress and completion.

Owner visits are necessary, but they can also be disruptive. It is better to establish clear written guidelines about their timing and frequency at the contract stage.

Enlisting an external surveyor for periodic inspections can safeguard the Yard's and the Owner's interests. A well-qualified Owners Rep is also very helpful. Still, they must also positively manage the Owner and Yard relationships and not engage in scoring points.

Contracts and Project Management

Contracts should be comprehensive, clear, and concise, covering all agreement aspects without complexity or overreliance on legal speak.

Contracts of often misunderstood or selectively read. It is useful to write a summary of how they flow for your own edification before committing to anything complex.

Owners should consider ways to manage potential currency and inflationary risks, such as buying currency forward, buying equipment early, or simply understanding that a risk exists. In an inflationary world this goes a long way to wards mitigating project risk so show flexibility.

When building in Turkey, the ownership of the hull and all fittings remains 100% with the owner providing all outstanding invoices are satisfied. This law in Turkey is designed to provide owner assurance throughout the building process.

Project specifications and quality standards must be clearly defined to avoid future surprises for either party.

Project progress should be verified, and both parties should clearly document the remaining time. For personal and cultural reasons, the Yard will always be tempted to insist that all is on time when that is not true.

The time to discuss delays is when there is time to effect remedial action. There is no time to have this conversation after a missed launch date.

Payments should be tied to agreed milestones rather than a monthly percentage to account for potential project deviations.

Yards and owners' sea trials need to be clearly specified, with minimum requirements outlined.

Defined Terms

Owner/Owners – "you," the body that has commissioned the build and, under the law in Turkey, is the legal Owner of the vessel in build.

Yard – the shipyard, in this instance, Naval Yachts

Naval Yachts – see Yard.

Artnautica is the design authority for the basic LRC and XPM ranges of high length-to-beam hull ratio and rugged Explorer Yacht designs.

Final Thoughts

There will be a constant stream of issues toward the end of your build. How we approach those problems greatly affects the journey itself. There will be points where murder is considered by both parties, so keep your eye on the end game and adjust your responses with that goal in mind. There are always solutions, whether acceptance, an engineering alteration, or an alternative path.

The owner and the Yard have the same objective: a successful launch. It is best to resist the temptation to blame or otherwise become adversarial.

This photo walks the talk. For more information and to see how our own build progressed, www.exploreryacht.com

Reminds me of the old adage: How does one eat an Elephant?

(Ans. One Bite at a time)